Customer's Expectations

> Eliminate the possibility of production stops due to foreign particles on the material

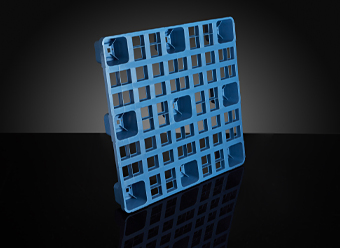

> Correct dimension of the part.

> Compact mould solution.

> High structural result. Need to move weld lines where they vwill not create internal stress or weak points.

> Complete filling of all the ribs and walls.

> Limit the injection pressure considering the customer machine indications.

> High production volume.

Our Solution

To provide a properly filled part, we considered the maximum amount of injection points.

The solution designed is optimized for parts of 100% regrinded material. This system configuration has increased the productivity and prevented issues caused by foreign particles on the material.

A rheological analysis has been performed to evaluate the filling pattern of the cavity; it highlighted also warping areas, some possible weak spots across the structure, and it defined the optimal cooling layout across the cavity block.

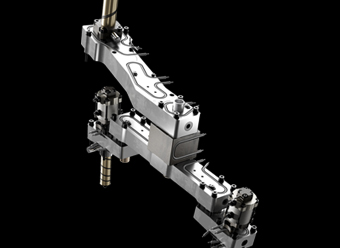

Oerlikon HRSflow system

The hot runner system is configured with 8 conical valve gate drops, hydraulic activation equipped with Oerlikon HRSflow Fail Safe. The solution has also been proven to be fit for stack mold solution according to your productivity needs.