Customer's Expectations

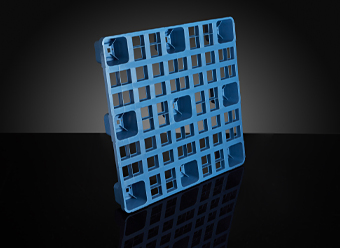

> Reduction of the total part weight and material used

> Correct dimension of the part.

> High structural result. Need to move weld lines where will not create internal stress or weakpoints.

> Complete filling of all the ribs and walls.

> Reduction of the cycle time.

> Reduction of the colour change number of scraps.

Our Solution

- Using the rheological simulation, the part design was updated for filling, pressure and warpage optimization

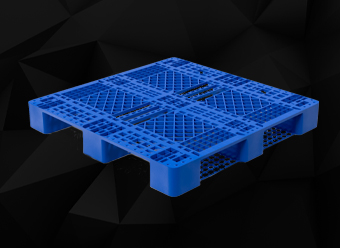

- HDPE and PP used successfully

- Cycle time reduced by -23%

- Achieved the weight reduction target

The same base was used for the complete range of containers height.

Oerlikon HRSflow system

The hot runner system is composed by 8 drops conical valve gate Aa series hydraulic actuation. The injection was direct on the part for all the gates with through the cavity end ring.

Partnered with Mundimold, Plastimol.