Customer's Expectations

> Fast colour change to reduce the scrap percentage

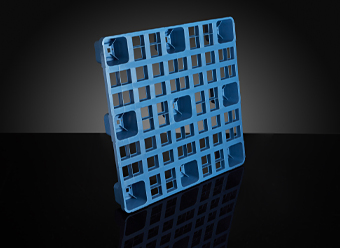

> Correct dimension of the part.

> High structural result. Need to move weld lines where will not create internal stress or weakpoints.

> Complete filling of all the ribs and walls.

> Limit the injection pressure considering the customer machine indications.

Our Solution

To provide a properly filled part, it was considered the maximum number of injection points.

The solution selected (Aa series and valve gate type) is ideal for those parts with requirement of high structural resistance because it is injecting the expected quantity of material.

For the correct filling of the walls a CAE analysis was performed, this indicated also deformation areas and eventual weak points in the structure. Using the analysis result it was possible to suggest the proper cooling line on the mould.

Minimum flow diameter considered for getting a fast colour change.

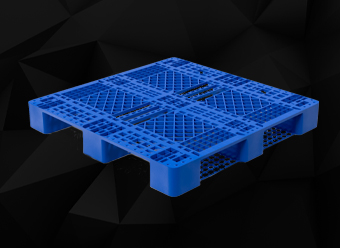

The solution applied can be used for many different bin dimensions.

Oerlikon HRSflow system

Our system is a 4 drops As series conical gating with hydraulic actuator free flow. All gatings diameter of Ø7mm with through the cavity end-rings.