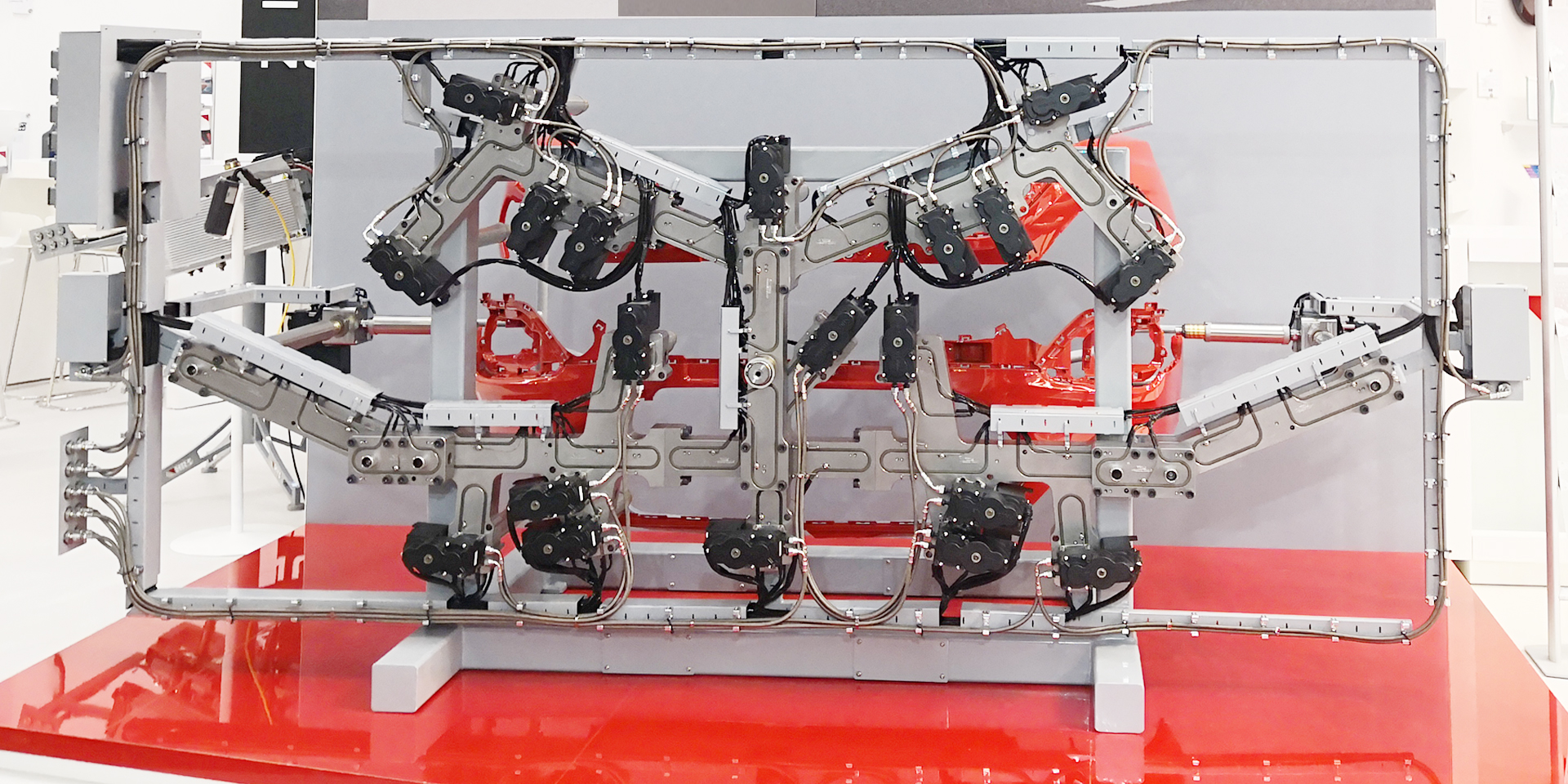

FLEXflow for Family Mold: different parts in a single shot and aesthetic performance at the same time

Efficiency and high quality: you no longer need to choose between the two!

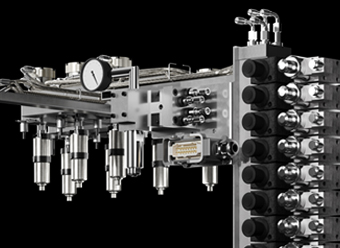

Family molds for the cost and time efficient production of different parts in a single shot, have traditionally been associated with problems caused by traditional pin control methods, including poor balancing causing e. g. warpage issues.

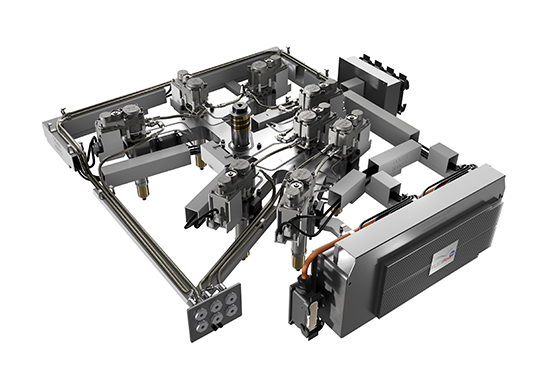

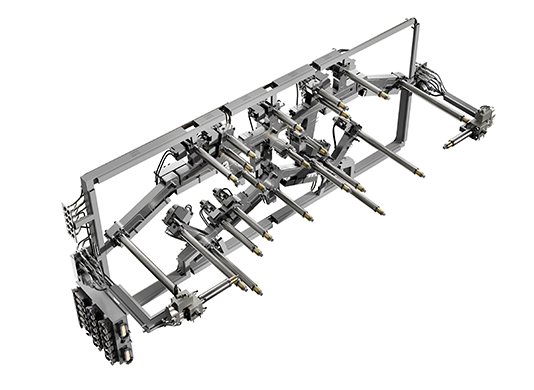

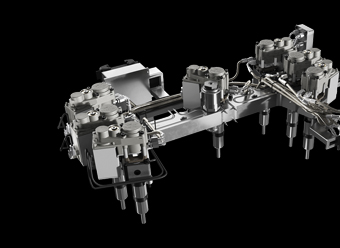

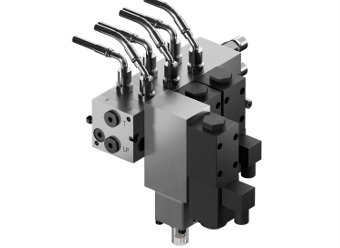

FLEXflow hot runner technology provides a broad potential to improve the quality of the parts, to avoid cost for additional process tuning, to broaden the process window and to extend lifetime of the tool. Using FLEXflow servo driven valve gate technology to independently control stroke, timing and force of each individual pin, can overcome existing limitations in terms of close similarity in size, weight, wall section and volume, whilst ensuring all cavities are being filled simultaneously, preventing from overfeeding and flash formation.