Fast injection and cycle times in a stable process

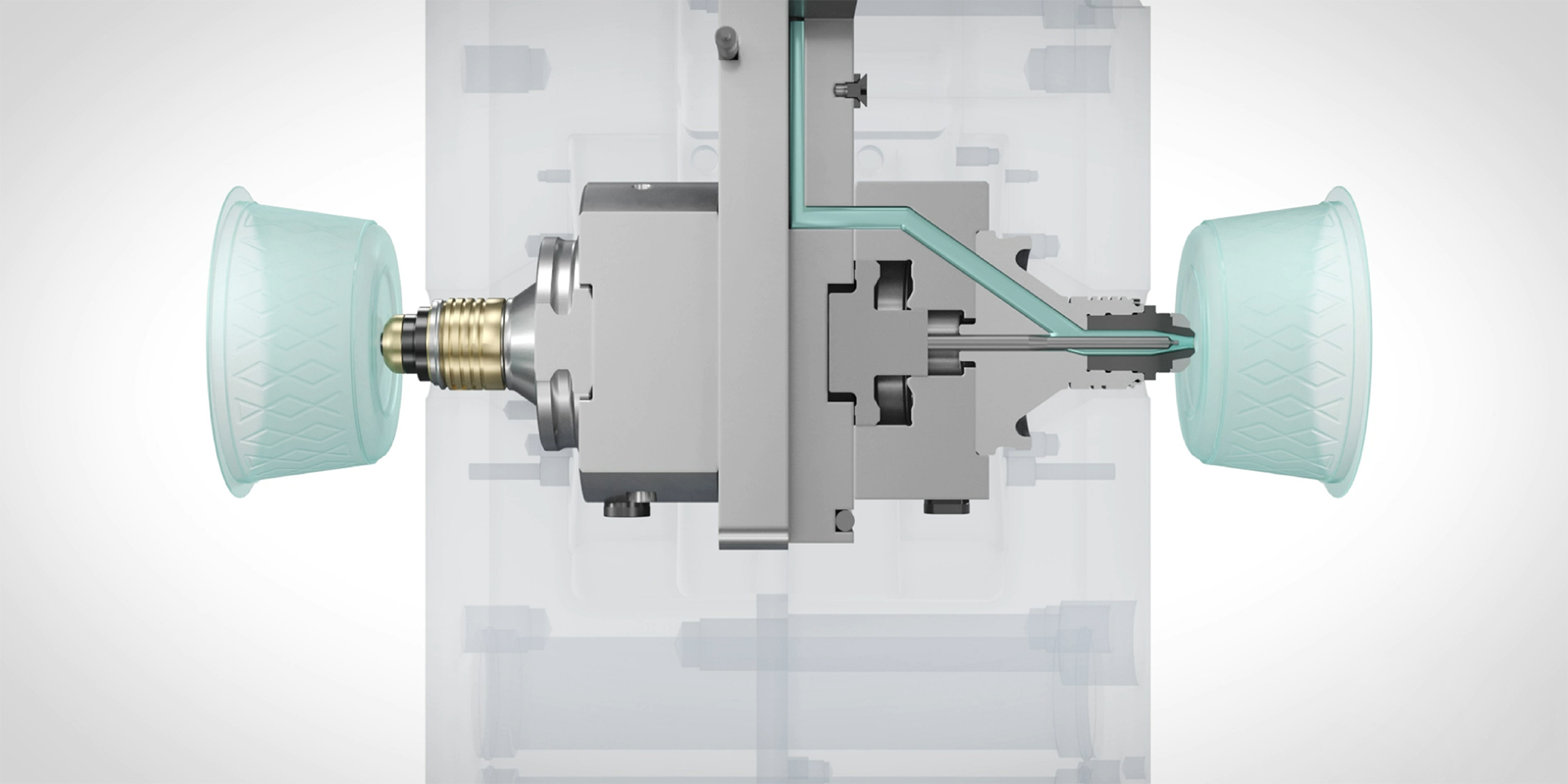

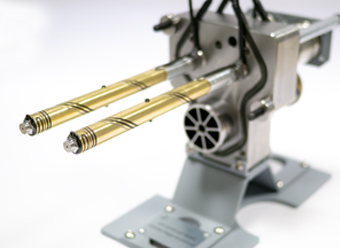

Designed to withstand high filling pressures, the new compact stack mold (patent-pending) is equipped with the Xd nozzle series engineered for thin wall packaging applications. This new solution (soon available on the market) enables fast injection and cycle times in a stable process with high part weight consistency. Moreover, assembly and maintenance are extremely simplified and highly efficient thanks to a plug-and-play installation.

This hot runner system, which enables the use of smaller injection moulding machines, fits a maximum plate thickness of 220 mm and a minimum distance of 260 mm from gate to gate of coaxial nozzles.

A demo tool equipped with this new technology is available in our Test Lab for our customers to try their most challenging polymers.

This new solution has also been developed to process PCR resins and biopolymers according to future needs which are increasingly connected to Circular Economy.