High performance systems for small precision parts

Oerlikon HRSflow multi-cavity line for small applications is designed for low shot weights ranging from 0,5 to 60 gr according to the polymer used. For open gate the minimum gate to gate pitch is 22 mm with the smallest nozzle pocket of Ø 16 mm. For the valve gate the minimum pitch is 40 mm using the on plate cylinder (it gets to 25 mm with MultiValve Plate). With the cylinder on manifold the minimum pitch between drops becomes 37 mm.

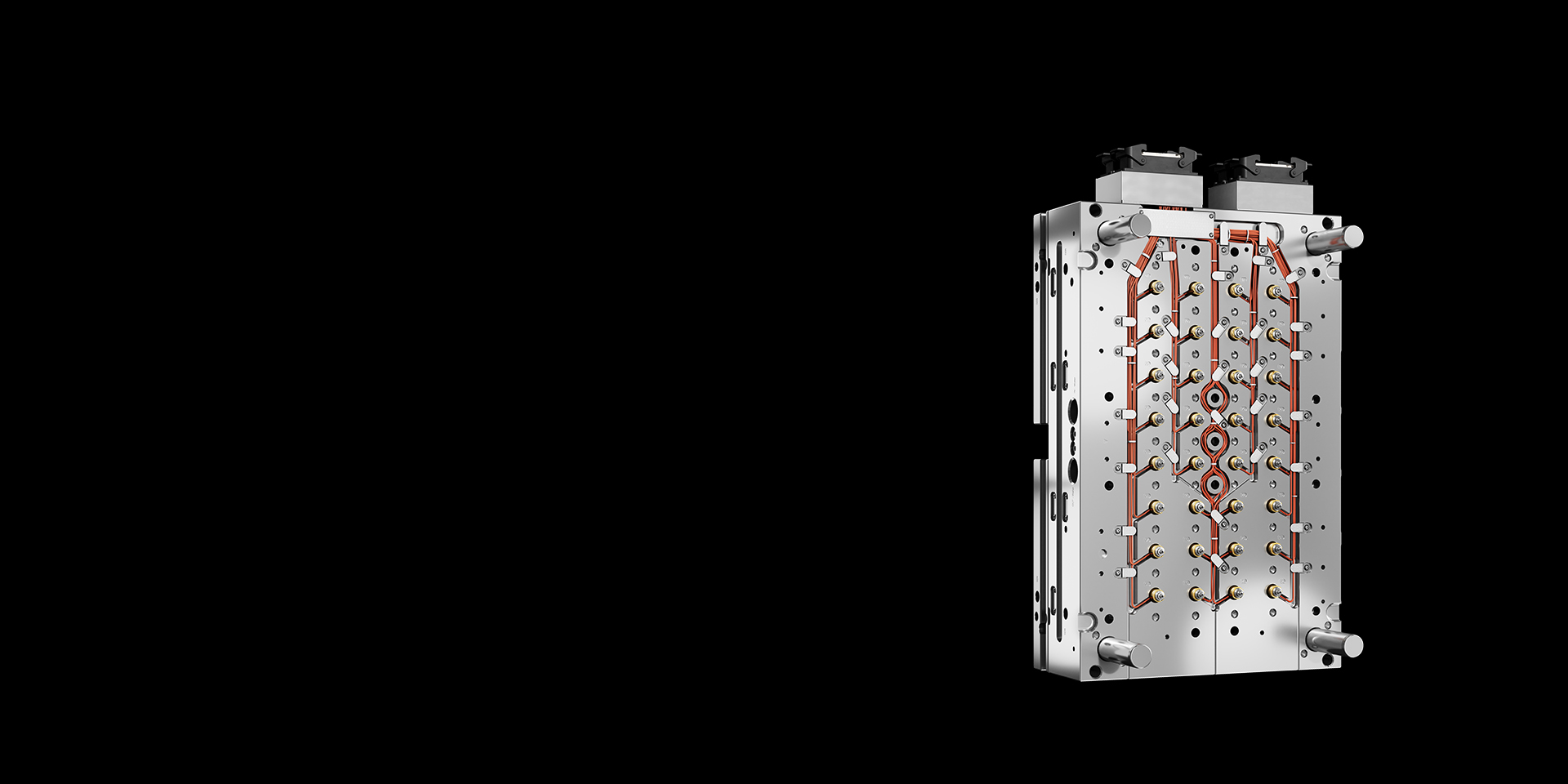

Our hot half is a fast plug and play solution for the injection molding machine. The internal geometry is suitably profiled to guarantee excellent resistance to bending and torsion, even with high cavitation numbers. Our dedicated channel design and a specific coating significantly increase the wear and tear of components, performing also optimized corrosion resistance.

Our commitment to a strong sustainable future for our planet

Biopolymers and PCR resins have dedicated technical solutions, as they are often characterized by narrow process windows due to thermal or shear sensitivities.

Our systems are furthermore conceived to prevent damages caused by foreign particles accidentally present in the PCR compound, to avoid any streaking or flow marks that could jeopardize the cosmetic and functional result of molding.