Our Solution

Oerlikon HRSflow advocates the combination of FLEXflow HRS and sequential injection to maximize efficiency in both filling and packing for demanding geometries.

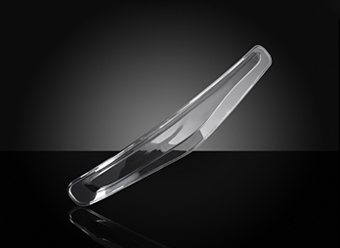

FLEXflow HRS, with its potential, allows precise management of flow rates and pressure at each gate location. Accurate stroke and speed settings ensure worry-free sequential injection on crystal-clear polymers. Hesitations and flow marks, typical of sudden pressure drops, can be controlled based on product needs, resulting in the highest surface finishing.

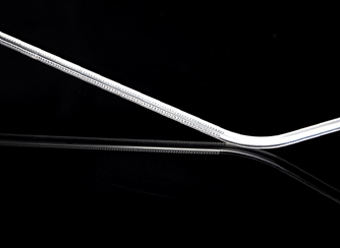

Oerlikon HRSflow system

A perfectly sealed Screwed-In hot runner with three valve-gated orifices on each cavity and each shot, totaling 12 nozzles. Pre-engineering stages and rheological studies demonstrate how parts and processes can benefit from the use of servos instead of traditional pneumatic or hydraulic activations.